The Role of Talent Development in Strengthening Domestic Semiconductor Manufacturing

As the semiconductor industry faces increasing global demand and geopolitical pressures, domestic production has become a strategic priority for many nations. Erik Hosler, an expert in semiconductor innovation, recognizes that achieving this goal requires more than just advanced machinery and cutting-edge facilities—it demands a skilled workforce capable of driving innovation and maintaining operational excellence. Talent development, supported by robust training programs and partnerships with academic institutions, is at the core of strengthening domestic semiconductor manufacturing capacity.

Building a Workforce for the Future

Semiconductor manufacturing is among the most technologically complex industries, requiring expertise in areas such as materials science, engineering and advanced robotics. To meet these needs, companies are investing heavily in specialized training programs to upskill existing employees and attract new talent. These initiatives provide hands-on experience with the latest manufacturing technologies, preparing workers to manage intricate processes like extreme ultraviolet lithography and automated production systems.

Academic partnerships also play a pivotal role in workforce development. Collaborations with universities and technical colleges ensure that future graduates possess the skills needed to succeed in the semiconductor industry. By aligning curricula with industry requirements, these partnerships help close the talent gap while fostering a pipeline of highly qualified professionals. Such collaborations also drive research initiatives, enabling the development of innovative technologies that further strengthen the industry’s competitive edge.

Enhancing Domestic Manufacturing Capacity Through Talent

A skilled workforce is critical not only for maintaining production standards but also for driving continuous improvement and innovation. For instance, teams proficient in advanced data analytics can optimize production efficiency by analyzing process metrics in real-time. Similarly, expertise in automation and AI enables companies to implement smarter manufacturing solutions, reducing costs and enhancing scalability.

Erik Hosler highlights that “Accelerator technologies, particularly in ion implantation, are enabling manufacturers to push the limits of miniaturization while maintaining the integrity of semiconductor devices.” These advanced techniques allow for precise control over dopant placement, enhancing performance and efficiency in next-generation chips. As semiconductor scaling continues, ion implantation plays a crucial role in meeting the industry’s demand for smaller, faster and more reliable electronic components.

A Foundation for Growth

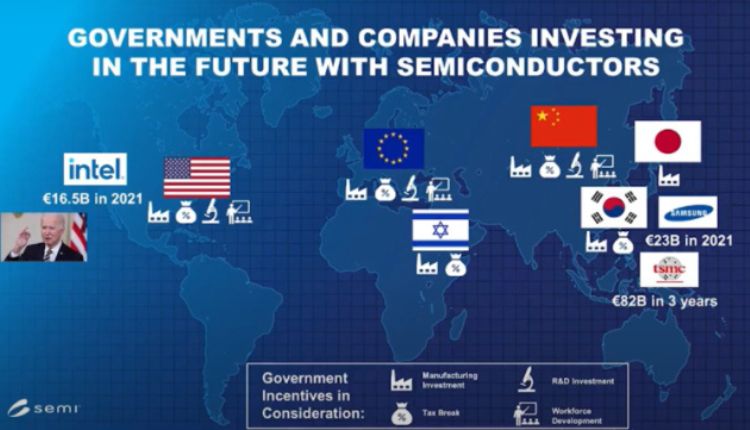

As governments prioritize reshoring semiconductor production, talent development is key to success. Investments in education, training and academic partnerships expand domestic manufacturing capacity while fostering long-term competitiveness. A skilled workforce ensures manufacturers can adapt to industry advancements and maintain a strong global position. These efforts also drive innovation critical to sustaining growth.