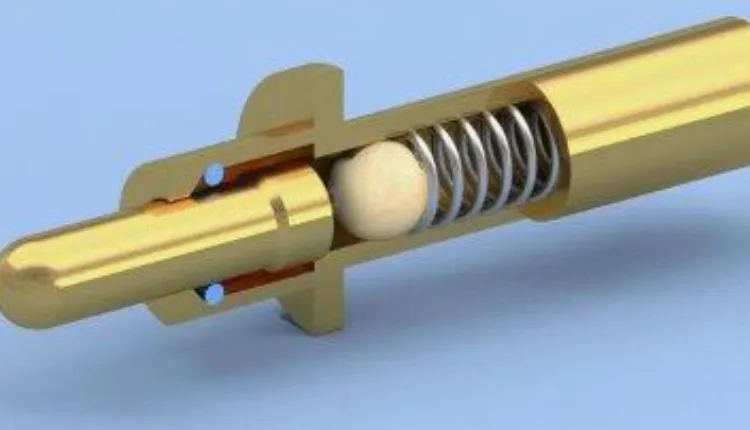

A pogo pin spring loaded pin is a type of electric connector that is commonly used in many modern electronic devices and the electronics testing industry. It is also known as a spring-loaded pin because it uses an integrated helical spring to apply a constant normal force against the back of the mating receptacle or contact plate.

Stability

A spring-loaded pin is a type of electrical connector mechanism that makes stable electric contact with a mating receptacle. It is widely used in a variety of electronic applications and in the test industry. These pins are designed for use in applications that are subject to shock, vibration, and other factors that may damage other types of connectors. They are also very durable and can resist corrosion.

Another feature of these pins is that they have a small size and are easy to manufacture. This makes them one of the most popular types of connectors in the electronic devices sector. These parts are fabricated using a turning and spinning process that does not require a mold, enabling them to be produced in smaller quantities at a lower cost than other contacts. In addition, these components are available in tape & reel packaging to help increase stability for PCBs.

Durability

Pogo pins, or spring loaded pins, are a type of connector that is commonly used in digital devices and circuits. They are a popular choice for a variety of reasons, including their durability and reliability. They are also a good choice for applications that require a space-saving design. This is because they don’t require as much physical contact between the two parts.

In addition, pogo pin are durable and can withstand the stresses that come with normal use. They can be used in a wide range of applications and are typically less expensive than other types of connectors. Spring-loaded pins, sometimes referred to as push-pull or pogo pins, are a reliable, precision made interconnect solution ideal for a variety of demanding application requirements in the fast moving world of electronic interconnects. They are backed by a great warranty and can help manufacturers meet new safety standards. These include RoHS compliance. Choosing the right spring-loaded pin can ensure that your products are safe for consumers and employees.

Reliability

The reliability of pogo pin spring loaded pins is a key factor that has helped them become one of the most popular connector types in the electronics industry. Not only do these connectors offer great connections every time, but they also have a long life cycle and are backed by a solid warranty. Another reason why they are so reliable is that they’re RoHS-compliant, which means they’re safe for both workers and the environment. This is important as more and more consumers are becoming concerned about environmental issues and safety, which means that manufacturers need to make sure their products are safe for everyone.

Pogo pins are also incredibly easy to use, which makes them ideal for a wide range of applications. They can be used to connect many different devices to one another, including computers and cell phones. However, it’s important to choose the right pogo pin for your application so that you can get the best possible connection.

Cost

Pogo pin spring loaded pin are an excellent solution for many electronic applications. They are available in a variety of lengths, diameters and plunger types to fit your application needs. They are also very cost-effective. The pins are fabricated by turning and spinning instead of using a mold, which reduces production costs.

This has aided to make pogo pins a preferred type of electrical connector in the electronics industry. Their high durability and resilience to shock and vibration are excellent for a number of demanding applications. They are widely used in a wide range of electronic applications and are especially popular in the electronics testing industry, where they allow a more rapid way to connect external connections on a PCB. This saves board space and allows a faster, more reliable test process.

More Words

Often known as spring probes, pogo pins or spring loaded contacts, these compliant pins have been in use for decades. However, they can be a very expensive, labor intensive and unreliable contact solution when compared to modern pin technologies.

Misalignment issues associated with traditional pin and receptacle connections can lead to damaged contacts, missing connections and broken pins. This can be a major issue in automated component placement and manufacturing.